In the realm of industrial businesses, packaging plays a crucial role in maintaining the quality of plastic products and ensuring efficient logistics. However, certain packaging mistakes can negatively impact your operations, resulting in wasted resources and potential losses. Follow along as we shed light on common industrial packaging mistakes that can hurt businesses, with a focus on improving efficiency.

Neglecting Package Design

One of the most overlooked aspects of industrial packaging is the package design. Plastic manufacturing businesses often fail to realize that a well-designed package does more than protect the product—it also optimizes space utilization during transportation. Poorly designed packages can lead to wasted space in transport vehicles, increasing transportation costs and reducing overall efficiency.

Overlooking Material Quality

The quality of packaging material directly influences the protection of your products. Opting for cheaper, low-quality materials may initially seem like a cost-saving measure. However, these materials are more likely to fail during transportation or storage, leading to product damage and subsequent financial losses.

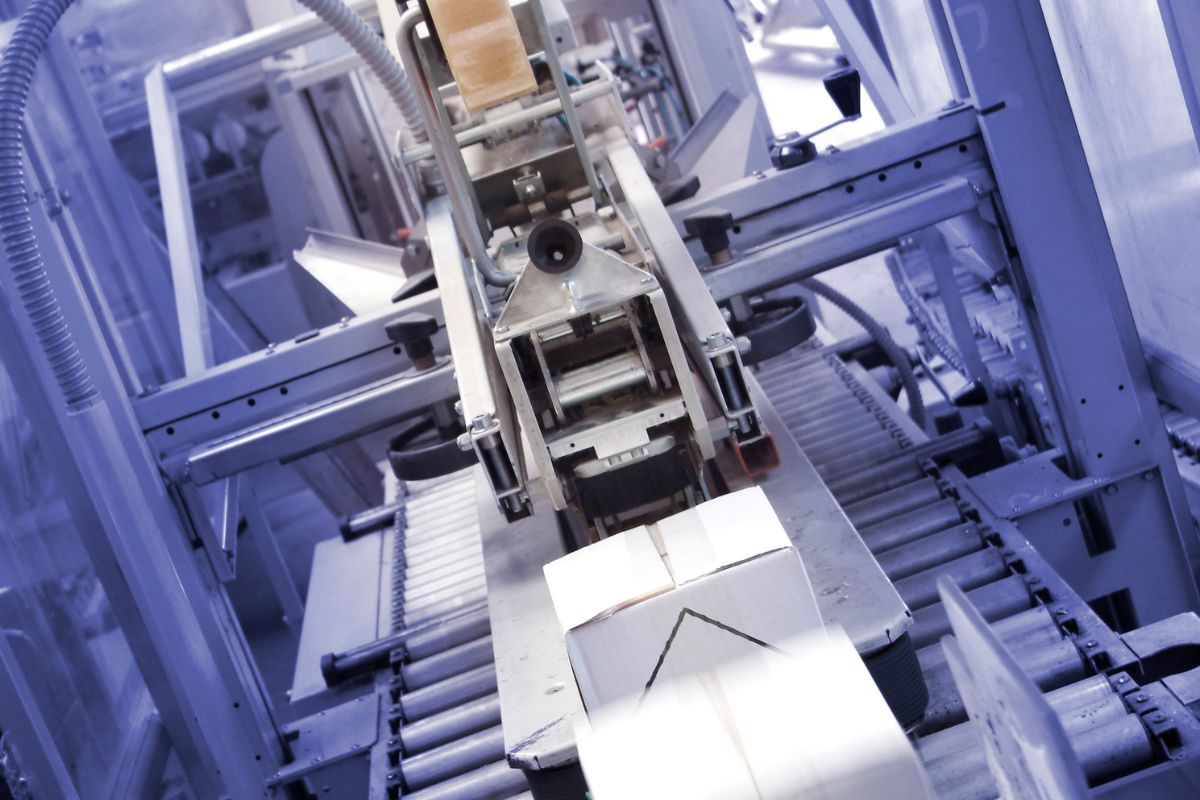

Stretch Wrapping Mistakes

Stretch wrapping is a common packaging technique in industrial businesses due to its cost-effectiveness and versatility. However, mistakes such as improper load containment, incorrect wrapping patterns, or using the wrong type of stretch film can cause product instability and damage. Ensuring proper stretch wrapping techniques and choosing the right type of film for your products can ensure effective packaging. It’s always beneficial to ask questions of your stretch wrap equipment manufacturer and ensure you’re using the proper machines for your product needs.

Lack of Regular Training

Industrial packaging techniques and technologies continuously evolve. Businesses that do not invest in regular staff training risk falling behind in implementing efficient packaging methods. This lack of training can lead to packaging errors, inefficiencies, and even workplace accidents.

Avoiding common industrial packaging mistakes can significantly improve the efficiency of your plastic component business operations. By investing in well-designed packages, high-quality materials, proper stretch wrapping techniques, and regular staff training, businesses can optimize their packaging processes. Remember, while these measures may require an initial investment, they can save your business from potential losses and inefficiencies in the long run. Effective packaging is not just about protecting your products; it is also about improving your bottom line.